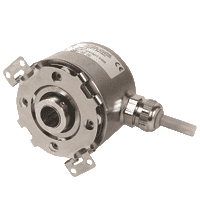

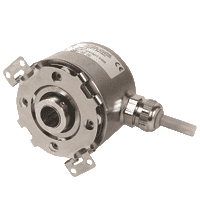

Pepperl Fuchs RSI58O-02YK1R61T-01024 Incremental Rotary Encoders Price & Specifications

Wireless No

Weight Approx. 350g

Voltage 10-30 V DC

Usage Industrial Automation, Motion Control Systems

Signal Type Quadrature (A, B, Z channels)

Sensor Type Optical Rotary Encoder

Sensitivity Standard Sensitivity for Industrial Encoders

Response Time <1 ms

Resolution 1024 pulses per revolution (PPR)

Product Type Incremental Rotary Encoder

Power Consumption Max. 1W

Output Incremental Encoder Signal, Push-Pull (HTL)

Operating Temperature -40A C to +85A C

Mounting Type Clamping Flange

Measurement Range 0-360A Continuous

Material Aluminium Housing, Stainless Steel Shaft

Interface Cable, Push-Pull (HTL)

Input Rotary Shaft Movement

IP Rating IP65

Function Measures Rotary Position and Speed

Features Compact size, Robust construction, Reverse polarity protection, Short-circuit proof outputs

Cable Length Standard 1.0 m (customizable)

Application Industrial Machinery, Robotics, Conveyor Systems

Accuracy High Precision, A 0.01A

About Pepperl Fuchs RSI58O-02YK1R61T-01024 Incremental Rotary Encoders Detail

Grab the new Pepperl Fuchs RSI58O-02YK1R61T-01024 Incremental Rotary Encoder, a grandiose solution for industrial automation and motion control. This premier encoder boasts phenomenal precision (0.01) and a high resolution of 1024 PPR, making it ideal for applications demanding dependable performance. Featuring a 10 mm stainless steel shaft, robust aluminium housing, IP65 protection, and CE/RoHS certifications, it offers durability with industry-leading accuracy. With a maximum output frequency of 300 kHz, 6000 rpm rotation speed, and a long bearing life, this rotary encoder is built for continuous operation. Take advantage of this exclusive offer for fabricators, exporters, manufacturers, and system integrators across India.

Versatile Applications for Industrial and General Uses

The Pepperl Fuchs RSI58O-02YK1R61T-01024 Incremental Rotary Encoder is engineered for both specific and general industrial applications. It is perfectly suited for usage in automation plants, robotics, conveyor systems, and various motion control setups. This device integrates seamlessly into processes requiring accurate rotary position and speed monitoring at both the site and plant levels, ensuring optimized workflow across diverse industrial machinery environments.

Reliable Shipment, Supply, and Certifications

This encoder assures prompt shipment and systematic packing & dispatch procedures, ensuring the safety of every unit during transit. With steady supply ability, bulk and customized orders are efficiently managed and exchanged when required. Certified with CE and RoHS compliance, every device meets stringent international standards, guaranteeing reliable service and consistent quality across deliveries to distributors, suppliers, and end-users.

FAQs of Pepperl Fuchs RSI58O-02YK1R61T-01024 Incremental Rotary Encoders:

Q: How does the Pepperl Fuchs RSI58O-02YK1R61T-01024 encoder measure position and speed?

A: The encoder converts rotary shaft movement into incremental signals with high precision (0.01), utilizing quadrature (A, B, Z channels) for accurate position and speed measurement.

Q: What are the main plant applications for this rotary encoder?

A: It is designed for integration into industrial machinery, robotics, and conveyor systems within automation and motion control plants, supporting precise monitoring and control.

Q: When can I expect delivery after placing an order?

A: Standard orders are shipped promptly, with lead times dependent on quantity and customization. Efficient packing, dispatch, and exchange processes ensure timely delivery and product integrity.

Q: Where can this encoder be installed?

A: The encoder can be installed at machinery sites, automation plants, and on-site conveyor systems using the clamping flange mounting method, suitable for industrial environments due to its robust design.

Q: What benefits does the grandiose design of this encoder offer?

A: Its phenomenal construction with an aluminium housing and stainless steel shaft delivers outstanding durability and reliability. The premier IP65 rating and certifications guarantee operational safety and longevityideal for demanding environments.

Q: How is the product supplied and protected during shipment?

A: Each unit is carefully packed and dispatched following stringent procedures. Industrial-grade packing ensures product safety, and exchange policies support customer satisfaction.